How To Streamline Your Inventory Management Procedures

Supply chain logistics requires careful attention, plenty of skill, and the ability to coordinate/plan effectively. Inventory management is an integral part of the pre-shipment stage of the supply chain and should not be overlooked. Plenty of issues can pop up at the inventory management level of the chain. These might include theft, shortages, overstock, and more. Further compounding matters, there may be unauthorized purchases made that are added to your inventory or other fraud channels happening right before your eyes. To improve visibility into your inventory, you’ll need some additional tools. Today, we’re going to cover some of those tools and how they can help you streamline your inventory management procedures.

Use Guided Buying

The first step to better inventory control is improving the buying experience. Guided buying is a helpful way to reduce inventory issues and maintain the right levels of stock. In guided buying, employees make purchases from a pre-approved list. These lists are curated by curated by approved vendors, and they’re known as punch out guides. With guided buying in place, employees are restricted to making purchases that are approved and in compliance with established company inventory protocols. Not being able to purchase unauthorized items saves the company money and reduces inventory control issues down the line.

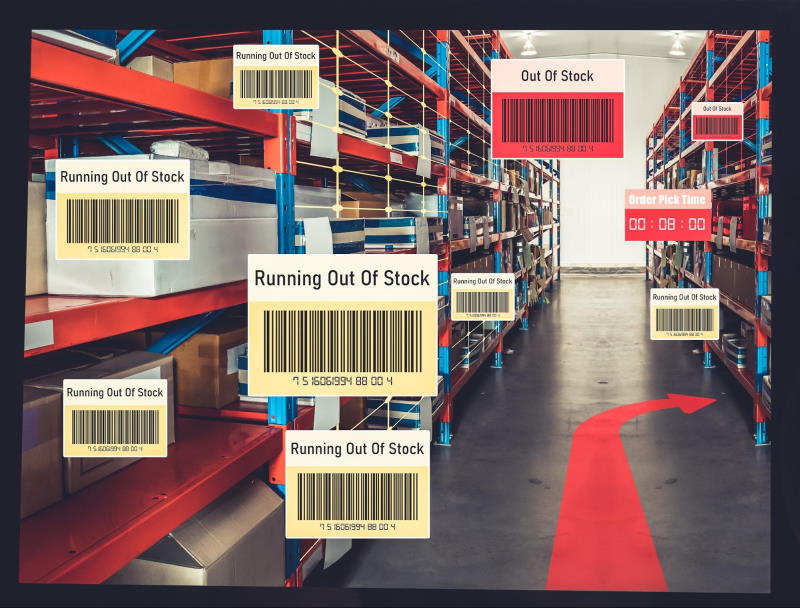

Improve Visibility

A large part of running a stock really is having visibility into what’s on hand, what you need, and cash flow. At its most basic definition, visibility is just being able to track your inventory and see what’s happening with it in real time. Visibility works hand in hand with guided buying. By providing a single shopping inventory, you can reduce excess inventory. Guided buying, as we mentioned above, can help out significantly. But it’s also vital to only purchase inventory from approved suppliers and limit items to your company’s own internal warehouses. Why? Because it increases visibility into your inventory procedures and increases warehouse efficiency. When you want to create a balance balance between supply and demand while also seeing what’s happening in your own warehouses, visibility is it essential to for doing exactly that.

Prevent Overstocking

If there’s one key component of managing a stockroom that should never get overlooked, it’s stockroom management. In inventory management, the stockroom is merely the space that holds the inventory. These might be warehouses or dedicated facilities. Either way, they require plenty of oversight. With that in mind, it makes sense that enhanced inventory control in the stockroom is crucial. Too little or too much stock can be a problem. It’s also not great if you can’t find anything in your stockroom! Overstock can be expensive, too. Money is wasted by acquiring excess stock in the first place. And maintaining storage space isn’t exactly free! There are a few ways to avoid overstock issues like frequently reviewing inventory levels and making adjustments as needed. It’s also prudent to only order what you need and make sure you’re using a strong tracking system. Although the key to preventing overstock is to be proactive, sometimes it can’t be helped. In those situations, develop a strategy for reducing overstock such as liquidating, donating, or using them as the basis for promotions.

Watch Out For Fraud and Theft

Warehouse fraud and theft: the very words send chills down every manager’s spine. It may not seem obvious, but fraud and theft have the potential to run rampant at warehouses across the country. The statistics are shocking, sometimes, too. Prevention starts with education. How did it happen in the first place? Sometimes thieves will steal products off the track or falsify records to make it seem like there’s less product coming in than there actually is. This is akin to removing goods from inventory without recording it. Sometimes items can be stolen from the loading dock or pallets, further compounding the problem. You need to have an inventory system that helps you manage and track inventory movements in real time. This is where visibility and guided buying come into play to help prevent theft. Employees also need to be vigilant to watch out for any potential theft. Employing security cameras and other security measures can also help. When you’re trying to determine if somebody is stealing, watch out for fudge reports, consistent data, and employees suddenly living far beyond their means. These are all potential signs that a theft may be happening.

Implement Software Tools

Technology is a truly remarkable thing—and it’s practically essential for managing or running an organization in 2022 (and beyond). It can be your best friend for preventing overstock, inventory tracking, and other issues. Using automated inventory management, it’s easy to track inventory levels and movements. This gives you an eye on the happenings within the organization and supplies valuable information for reordering. Software can help you also set reorder points and minimums to ensure you never run out of stock (and also avoid overstocking). Instead of searching through manual reports and crunching numbers, you can take advantage of automation to explore inventory trends. With valuable insights into inventory trends, problems, buying it, and on hand levels, you can manage your inventory with great efficiency.